BIM in Boehler Industrial Construction

Boehler Edelstahl in Kapfenberg is investing in an additional, modern forging plant to manufacture high value and high quality products from stainless steel and special alloys for industries such as the aviation and energy sectors.

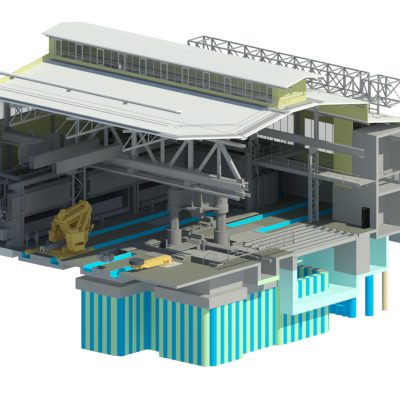

The project will be carried out by Thomas Lorenz ZT GmbH using the BIM-method. The basis is a digital model of the building that includes the complete inner equipment installation of the plant. This will ensure the early identification of conflicts between construction and installation.

The complex geometry of the concrete required for the pressing areas that are up to 11m deep, were developed in a three dimensional model using the Revit program based on the requirements from the plant engineering company. With planning workshops with this company, the model was directly adapted, the detailed planning and progress were updated in the model live. The release process was also done from within the model. The building model was not just the source for all building plans, but also all measurements and tenders could be generated directly from the model. Following the completion of the project, the digital model will be handed over to the principal’s facility management team.

Share this post:

Facebook

Twitter

LinkedIn

WhatsApp

E-Mail

More news

Conversion of the Ordensklinikum Linz BHS – Construction progress

27. September 2024

Disc golf workshop – team building at the end of the summer

20. September 2024

AKH CTMT Vienna – Construction progress

26. July 2024

New bridge support structure in just 1 week

21. June 2024